Backyard Mamma is pleased to welcome Steve Goodale, better known as swimmingpoolsteve.com, from Ontario, Canada as a guest blogger. Steve is a second generation pool builder and has a wealth of knowledge about swimming pools and shares tips to prevent early pool equipment failure.

Swimming pool equipment is expensive and it stands to reason that every pool owner would want to get the longest possible service life from each component of the system. What can the average pool owner do to make sure that their equipment lasts as long as possible? Consider this list of the most common causes for premature pool equipment failure:

1) Poor water maintenance and balancing

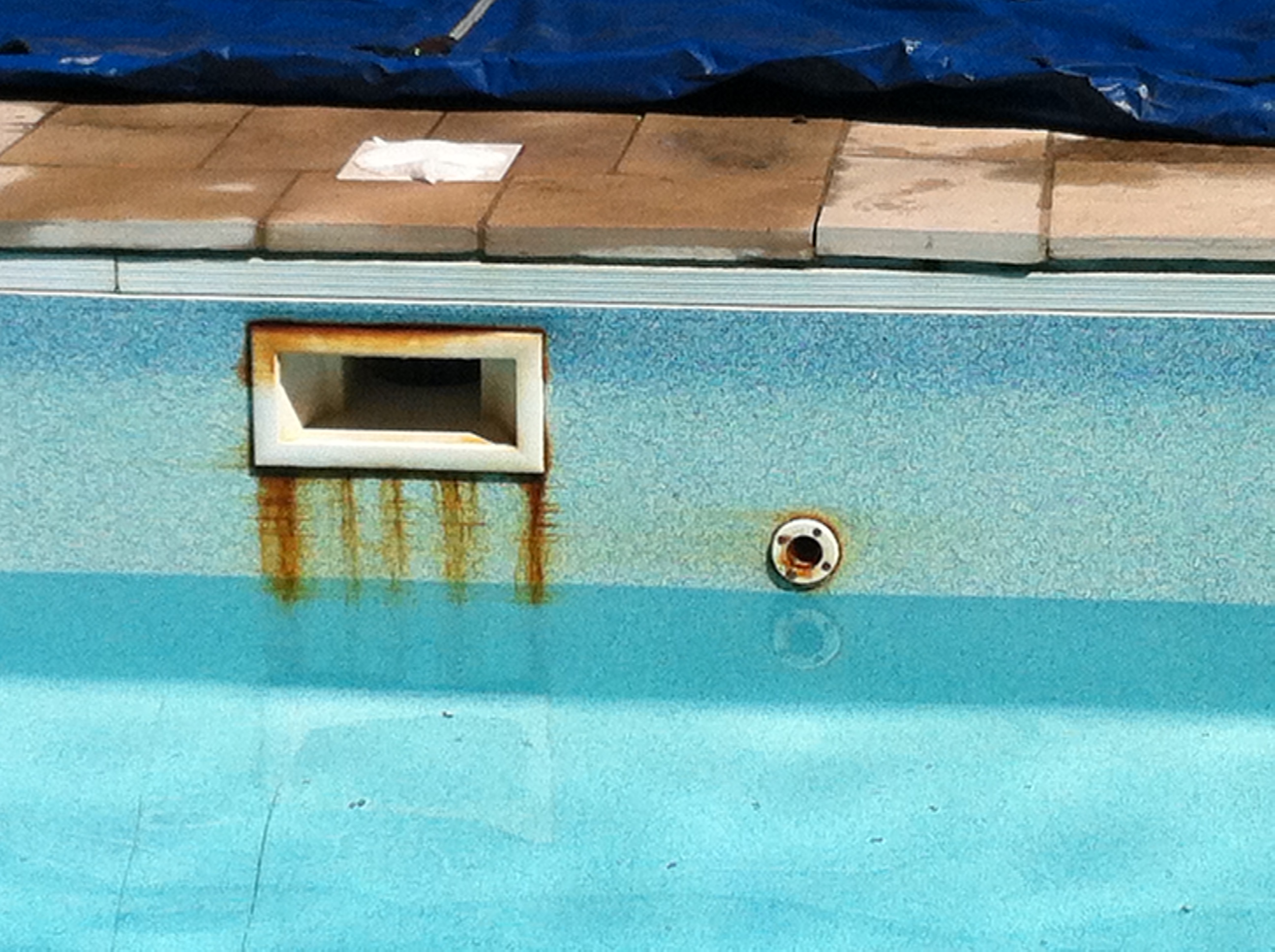

Poorly balanced swimming pool water is the number one thing that will cause early failure of swimming pool equipment. Water balancing is more than just creating a comfortable and safe swimming environment. One of the main reasons that you need to balance your pool water chemistry is to protect your equipment. As the values for chlorine, pH, alkalinity and calcium hardness in your pool fluctuate, the water can enter what is known as either a “scaling state” or an “acidic state”. During these periods of time where the chemical balance of your water is off, your pool equipment can sustain incredible levels of damage in relatively short periods of time. In addition to metals within the plumbing system starting to corrode, poorly balanced water can also result in metals and minerals coming out of solution from within the water and solidifying on the surfaces of your pool. These metals and minerals can cause undesirable textures to the interior surface of your pool as well potentially staining various components of your pool. If you want to do everything you can as a pool owner to prevent damage or early failure to your pool then the single most important thing for you to learn is how to accurately test and correct the water chemistry of your water. The importance of this can simply not be overstated.

Poorly balanced swimming pool water is the number one thing that will cause early failure of swimming pool equipment. Water balancing is more than just creating a comfortable and safe swimming environment. One of the main reasons that you need to balance your pool water chemistry is to protect your equipment. As the values for chlorine, pH, alkalinity and calcium hardness in your pool fluctuate, the water can enter what is known as either a “scaling state” or an “acidic state”. During these periods of time where the chemical balance of your water is off, your pool equipment can sustain incredible levels of damage in relatively short periods of time. In addition to metals within the plumbing system starting to corrode, poorly balanced water can also result in metals and minerals coming out of solution from within the water and solidifying on the surfaces of your pool. These metals and minerals can cause undesirable textures to the interior surface of your pool as well potentially staining various components of your pool. If you want to do everything you can as a pool owner to prevent damage or early failure to your pool then the single most important thing for you to learn is how to accurately test and correct the water chemistry of your water. The importance of this can simply not be overstated.

2) Inadequate equipment sizing & installation

If your pool equipment is not installed properly, or if you have the wrong pool equipment for your pool, then you will not get the maximum possible service life for your investment. Swimming pool pumps need to be sized based on the performance requirements of the pool. An average swimming pool needs to filter the entire volume of water of the pool between one to three times every 24 hours. If you prefer to run your pump only part of the day, then your pump needs to be able to meet this turnover volume with a reduced operating schedule. Once you know how much flow you need from your pump then you need to make sure that the filter that you have can handle the flow that your pump will be putting out. Newer variable speed pumps can be very powerful and can sometimes even be too powerful for smaller pool filters. Sand filters in particular are limited by the design of the multi-port valve, which is a flow restriction, and you need to make sure that your pump output will not exceed the maximum designed flow rate for your filter. Cartridge and D.E. Filters both can typically handle much higher flow rates than sand filters. You would be making a mistake to assume that the previous owners or installers of your pool equipment have made these calculations for your pool. Before you replace or install any pool equipment in your system be sure that you understand how much flow your system needs, and the maximum flow rates for any equipment that you have on your system.

If your pool equipment is not installed properly, or if you have the wrong pool equipment for your pool, then you will not get the maximum possible service life for your investment. Swimming pool pumps need to be sized based on the performance requirements of the pool. An average swimming pool needs to filter the entire volume of water of the pool between one to three times every 24 hours. If you prefer to run your pump only part of the day, then your pump needs to be able to meet this turnover volume with a reduced operating schedule. Once you know how much flow you need from your pump then you need to make sure that the filter that you have can handle the flow that your pump will be putting out. Newer variable speed pumps can be very powerful and can sometimes even be too powerful for smaller pool filters. Sand filters in particular are limited by the design of the multi-port valve, which is a flow restriction, and you need to make sure that your pump output will not exceed the maximum designed flow rate for your filter. Cartridge and D.E. Filters both can typically handle much higher flow rates than sand filters. You would be making a mistake to assume that the previous owners or installers of your pool equipment have made these calculations for your pool. Before you replace or install any pool equipment in your system be sure that you understand how much flow your system needs, and the maximum flow rates for any equipment that you have on your system.

3) Pool equipment bonding

4) Maintain the pool regularly

Regular upkeep and maintenance of your swimming pool is required to prevent more expensive repairs from developing. Much like maintenance for a car you will usually notice small deficiencies first in your pool. These could include tiles that are falling off, or a liner that is slipping out of the coping track as an example. Another much more commonly ignored symptom that would be a great example would be leaks in a pool. When you encounter a symptom of a deficiency you would be well advised to investigate it and attend to it quickly should a repair be needed. Ignoring small maintenance items like loose tiles, liner or interior surface problems, or leaks in the pool, are sure to add up to a much larger repair bill in the future. In almost every situation, a fast remediation of smaller and developing problems will help you to put off or avoid completely much more expensive and extensive repairs.

Regular upkeep and maintenance of your swimming pool is required to prevent more expensive repairs from developing. Much like maintenance for a car you will usually notice small deficiencies first in your pool. These could include tiles that are falling off, or a liner that is slipping out of the coping track as an example. Another much more commonly ignored symptom that would be a great example would be leaks in a pool. When you encounter a symptom of a deficiency you would be well advised to investigate it and attend to it quickly should a repair be needed. Ignoring small maintenance items like loose tiles, liner or interior surface problems, or leaks in the pool, are sure to add up to a much larger repair bill in the future. In almost every situation, a fast remediation of smaller and developing problems will help you to put off or avoid completely much more expensive and extensive repairs.

If you follow these four tips you should be able to avoid early pool equipment failure. Owning a swimming pool is a luxury, and is expensive, but with a proactive approach to pool care you can vastly minimize your expenses over the life of your pool.

Steve Goodale is a second generation swimming pool and spa expert located in Ontario Canada. Steve operates a popular online resource for pool owners and pool service technicians who want to learn more about swimming pools: www.SwimmingPoolSteve.com

Steve Goodale is a second generation swimming pool and spa expert located in Ontario Canada. Steve operates a popular online resource for pool owners and pool service technicians who want to learn more about swimming pools: www.SwimmingPoolSteve.com